Audit & Survey Services

SGIT has highly experienced and qualified engineers to carry out audit and survey on drilling rigs, marine vessels, production platform and power plants.

Our services include the five-yearly and Special Periodic Survey (SPS) inspection, reactivation inspection, as well as comprehensive reporting.

The electrical equipment we use is certified in accordance with the laws, regulations and standards set in most countries.

Safety, efficiency, and regulatory compliance are of utmost importance. An audit and survey service aims to provide an objective and independent assessment of these facilities, highlighting any issues that need to be addressed to ensure safe and reliable operations.

This service involves conducting comprehensive assessments and evaluations to ensure compliance with industry standards, regulations, and best practices. This is to help identify areas for improvement, ensure safety and regulatory compliance, and enhance operational efficiency in these critical industries.

Our Capabilities

Audit & Survey Services

Infrared Thermography Inspection Survey

Infrared thermography inspection survey provides a high-resolution, non-contact means of monitoring the condition of electrical and electromechanical equipment, roofing and wall insulation, and refractories.

SGIT’s team of qualified engineers and certified thermographers offer Infrared Thermal Survey on power switchboards, motors and mechanical equipment.

Our comprehensive reporting includes hotspot analysis with electrical anomalies found with colour photo documentation, infrared images, summaries of problems and recommendations of corrective actions to be taken.

In electrical applications thermography inspection, the Thermal Imager detects faults in electrical installation that usually appear as hot spots. These hot spots are often the result of faults such as increased resistance in a circuit, overloading, or insulation failure.

The more common applications for infrared thermography are:

- Inspection of Electrical Systems such as transmission lines, distribution lines, switchboards, transformers, circuit breakers, electrical panels and cables.

- Inspection of Mechanical Systems such as turbines, paper machines, motors, pumps, fans, heat exchangers, cement kilns, conveyor belts, and bearings.

- Inspection of Machine Structural Integrity such as boilers, chimneys, refractories, furnaces, flares, storage tanks, and pipes.

Such periodic infrared thermography inspection survey aids preventive maintenance and monitors processes to detect faults proactively. This in turn minimises downtime.

Vibration Inspection Survey

Machinery vibration, especially filtered spectrum, is generally the best indicator of rotating machine condition.

SGIT conducts vibration survey on motors, pumps, gearbox and marine structures (deck, bulkhead, piping, etc). Our services include:

- Periodic Monitoring Contract

- Permanent contract with in-plant placement of specialist/technician, with or without equipment

- Call out basis

- Packaged contract including supply of equipment & personnel, transfer of technology to plant personnel.

Drag Chain Repair And Build Services

Offshore cabling can suffer from severe wear and damage, especially in harsh environments where

cables are frequently dragged and battered throughout their day-to-day use. This can lead to deterioration of the rubber casing, exposing the wires underneath.

SGIT can rebuild the cable casing to its original profile using Belzona elastomer materials. This can be achieved via a 3D-printed former, which matches the exact dimensions of the equipment.

SGIT is also able to custom build your drag chain to suit your applications.

Our products are either designed to specification or based on a wide range of standard product options, but always customized to individual requirements. We use industry-relevant steel and plastic materials and follow all industry-relevant specifications.

SGIT provides full project management for drag chain services, including:

- Consultancy and Site Survey

- Engineering and Design

- Supply and Assembly

- Installation and Supervision

We offer full engineering support, and our focus is on quality and superior service, and our customers benefit from our extensive industry, product, and engineering know how.

Electrical Main Bridle And Sub Bridle

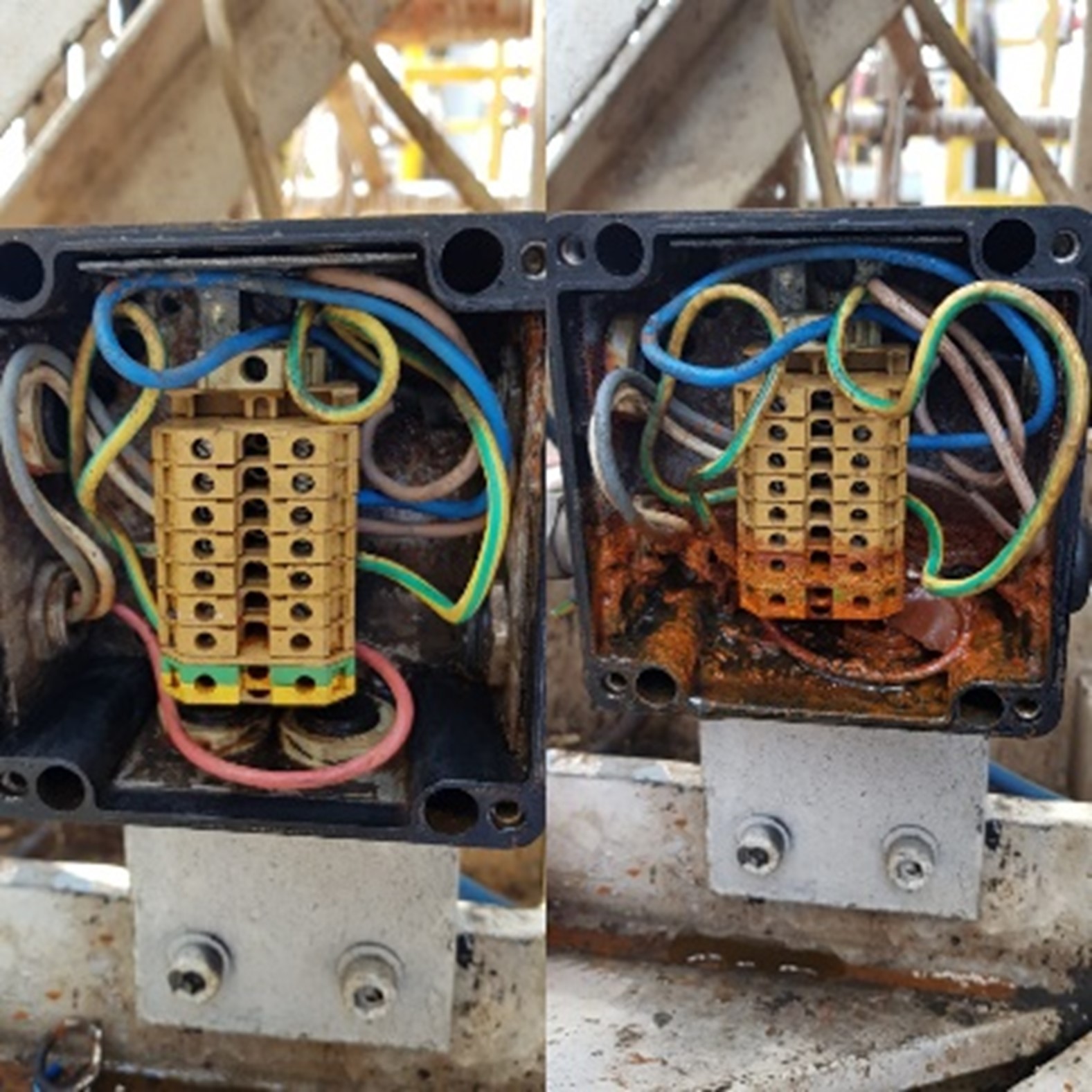

SGIT has extensive experience and expertise in offshore electrical main and sub bridle refurbishment, and over water umbilical connectivity projects, and offers precision-engineered turnkey cable assembly solutions for hazardous oil and gas applications.

Drilling operations and production facilities challenge cable construction with relentless heat, vibration, corrosion, chemical exposure and mechanical stress. Reliability is a huge issue because in today’s oil market, productivity is the key to profitability.

Wherever you are in the world, SGIT can provide cable products, service and solutions that are robust, longer-lasting, reliable, flexible and consistent, even in the harshest offshore environment.

Each bridle system presents unique engineering challenges that require experienced, innovative thinking to deliver connecting apparatus that provides reliable, efficient service in extremely harsh, dynamic operating environments.

Benefits:

Durability

Protective cover prevents abrasion

Ruggedized for marine environments

Bundles wound with uniform pitch and secured to neutralize stresses

Individually removable/replaceable loops

Ease of handling & Installation

No wire ropes required

Proven construction method

The scope of work includes, but is not limited to:

- Inspection of all cables, plugs and bridle parts (after disassembling the cable bridle)

- Report on the working condition of the Extension Cable Bridle

- Provide technician to conduct testing on existing fibre optic cables

- Repair damages to the cable sheath

- Replace and terminate cables and plugs that are beyond repair

- Re-use and cold galvanising all the existing block supports and steel hangers

- Service all the existing Crosby Wire Rope Clops with solution

- Perform Insulation Resistance Testing and Continuity

- Check on all the cables before and after repair/replacement

- Repair and service the plugs junction box.

- Prepare and submit Service Repair report after completion of job

Primary And Secondary Current Injection Testing

SGIT’s electrical testing services include Circuit Breaker Injection Testing, Protection Relay Testing & Calibration and Electrical Troubleshooting, Investigation and Inspection.

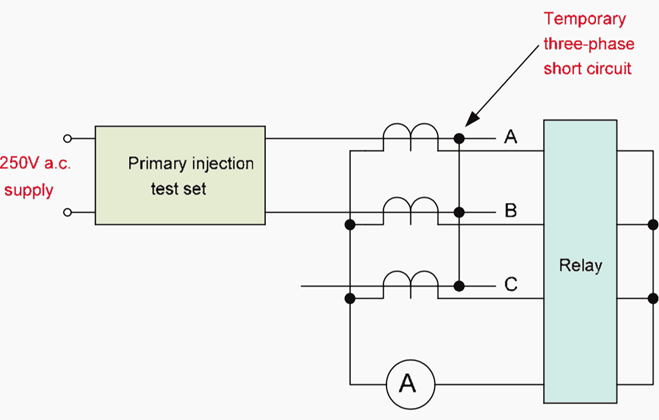

- Primary Current Injection Testing

Circuit breakers that are part of a critical process or engineered safety system are often maintenance tested using primary injection due to their high reliability requirements.

Circuit breakers that have thermal-magnetic or electromechanical trip units can only be verified for correct functioning via the primary current injection test method.

The primary current injection method is utilised in high current/high voltage scenarios at large electrical installations on the oil rigs and is usually the preferred test method because it includes the current sensors, wiring and the current conduction path in the circuit breaker with the test.

SGIT’s qualified technicians will inject the current into the system and measure if the breaker will trip or fail, and how long the current is live before the circuit is broken.

The Injection test set is capable of injecting currents up to 12,000 Amps and is fully portable.

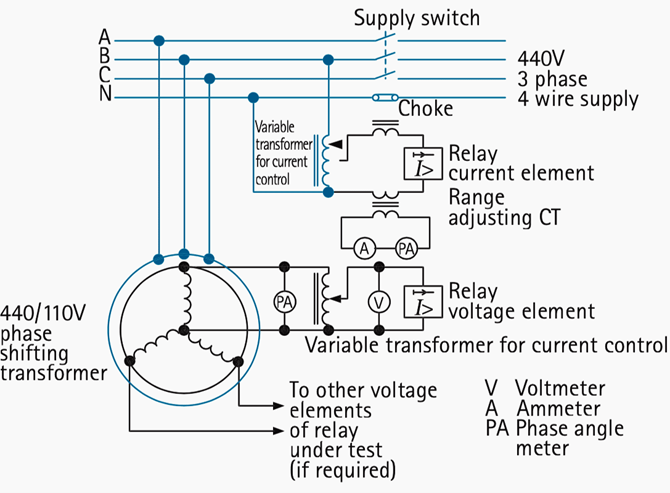

- HV/LV Secondary Current Injection Testing

Circuit Breaker and Protection Relay Secondary Current Injection testing and servicing is also carried out onsite.

We utilise Switchboard Panel Meter Calibration, and both single and three phase portable test sets.

Because primary current injection testing is a relatively expensive service, it’s usually performed only during the commissioning (start-up) process to supplement a program of periodic secondary-current testing.

Circuit breakers equipped with solid-state trip devices can be tested using secondary current injection, which requires less time and expense to perform the test.

QA/QC and FAT Services

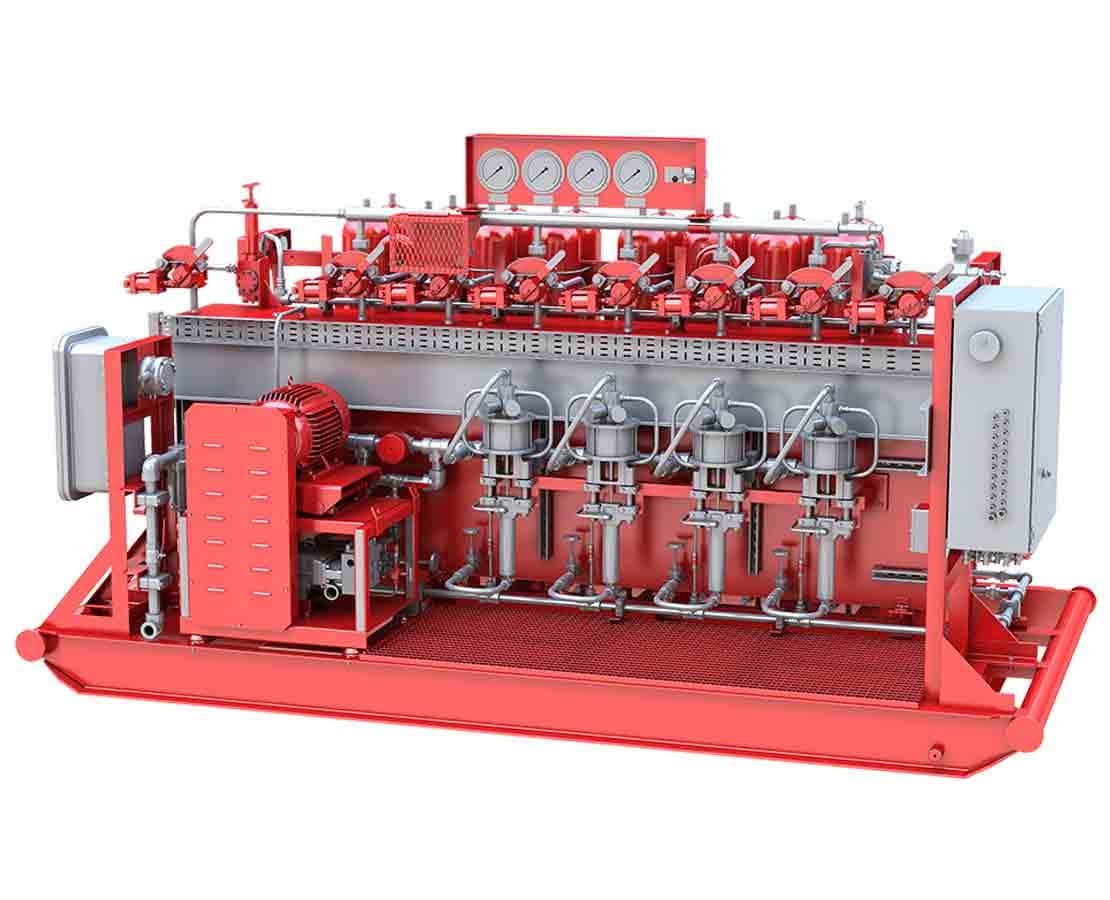

To assist Client in verification of OEM, API and Class standard requirements, SGIT provides QA/QC and FAT services and for new and/or major equipment overhaul at OEM or API certified facilities (vendor surveillance) including comprehensive reporting on equipment, such as:

- Top Drive (NOV, Lewco, Canrig, Tesco, Bentec, Aker).

- Blowout Preventer (BOP) system, surface BOP and subsea BOP (Cameron, NOV, Hydril)

- Subsea Drilling Risers, Buoyancy Modules, Telescopic Joints and Flex Joint (NOV, Hydril, Aker, Cameron, OilStates, DrilQuip).

- BOP Control and Accumulator System (NOV, Cameron, Hydril, CAD.

- Choke & Kill Manifold (NOV, SRI Energy, WOM, Hydril, Cameron, Aker)

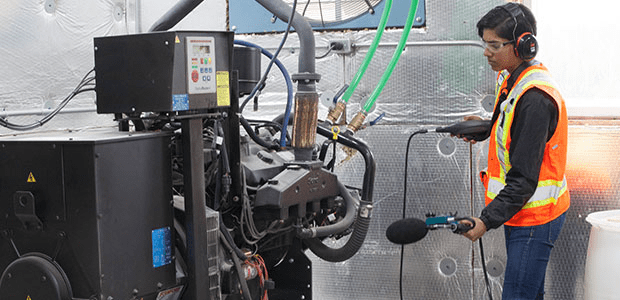

Noise Survey

Noise survey is another service which SGIT’s qualified engineers undertake at the workplace, machinery compartments and living quarters etc.

Greater productivity needs can often push production equipment to its limit. The appearance of any issues relating to noise, vibration and shocks can pose significant obstacles to operations, therefore it is of benefit to take preventive maintenance measures with SGIT’s noise survey.

Our comprehensive service includes reporting with analysis and recommendations on the following:

- Onsite Troubleshooting

- Redesign assistance (Vibration simulation, Noise map, simulation, durability)

- Airborne & structure borne noise (HSE, living quarters)

- Vibration analysis (structural modification, skid design)

- Machinery layout guidelines (mounting, installation, noise assessment)

- Validation & onsite measurement (FAT, Onsite measurement)

Request A Free Consultation With SGIT Now!

Contact Us Today !